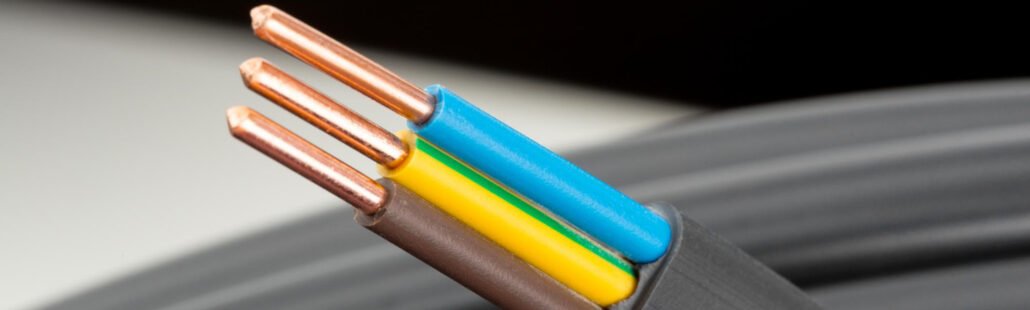

Are Copper Building Wire Manufacturers Changing the Future of Electrical Wiring in India?

Copper has over the decades been holding firm over aluminum as far as electrical wiring is concerned. Aluminum is lighter and cheaper but still the copper is chosen as a favorite among the manufacturers of electric wire and the manufacturers of electrical cables in India. However, why is copper so trustworthy and why are the best manufacturers still using it to wire its products?

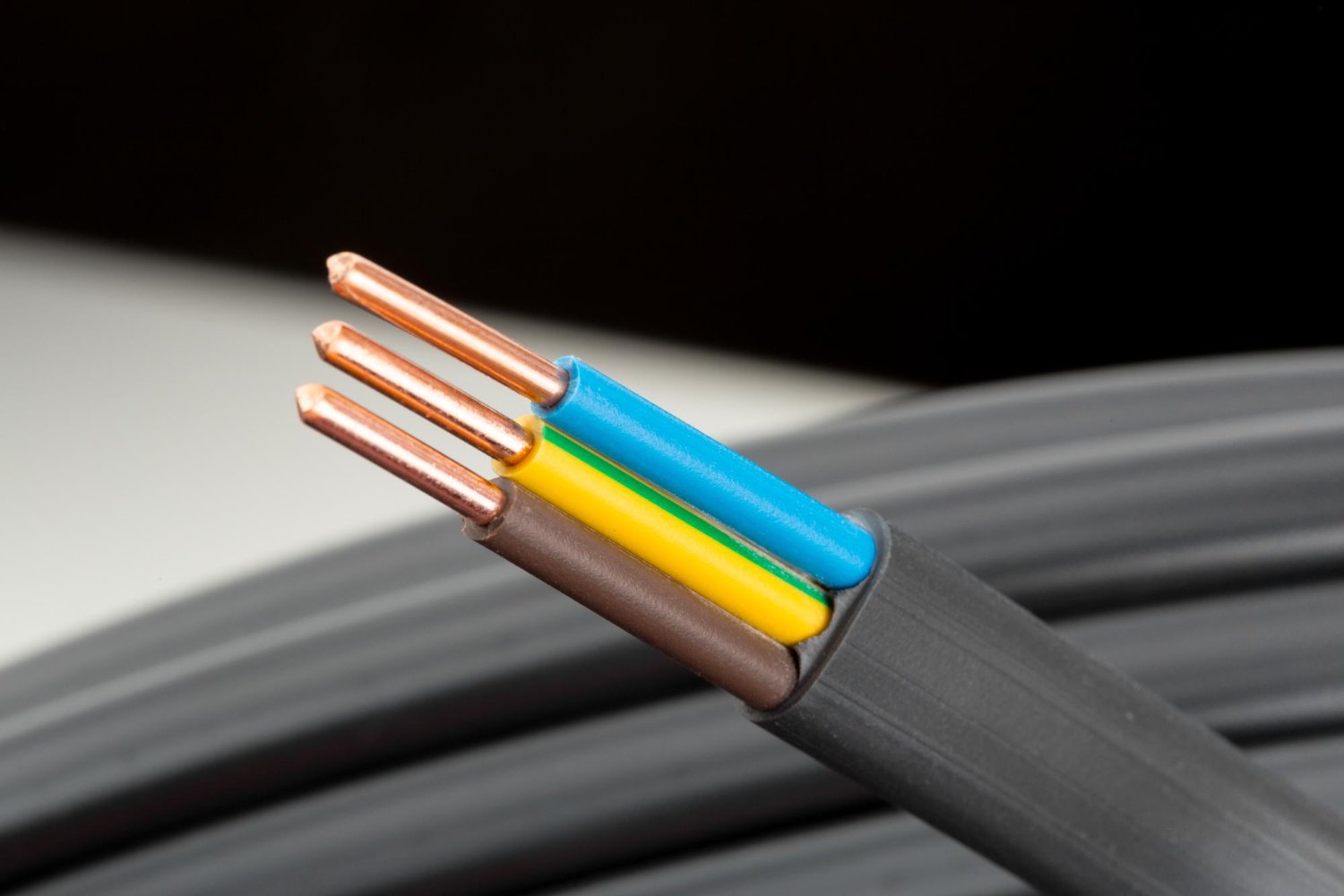

Superior Conductivity

Copper is famous in terms of exceptional electrical conductivity. It enables the flow of electric current with very little resistance and this is equal to less loss of energy. Comparatively, aluminum is approximately 61% the conductor of copper, implying that larger wires of aluminum are necessary to conduct the equivalent load as copper. This drawback can render aluminum less feasible in those high-performance wiring tasks such as multi strand of copper wire utilized in contemporary houses and power plants.

Durability and Strength

Copper has strength and durability and these are one of the most important pros over aluminum. Copper wires are also less likely to stretch or break, hence they are more useful in the long run. Aluminum is soft and prone to fatigue and fracture with time even in high stress and bending applications which may be multi strand electrical cable or underground wiring. This explains why most manufacturers of power cables in India have been using copper in order to have a long-term electrical installation.

Resistance to Corrosion

Copper is inherently resistant to corrosion and this makes it reliable in different conditions. However, aluminum is easily oxidized and the non- conducting layer is formed on the surface. This may cause increase in maintenance and even safety threats. In household wiring or even in industrial installations, copper has a longer lifespan and less service requirements; hence it is the preferred option.

Compatibility with Devices

The better conduction of copper also enables it to be compatible with the new-day electrical appliances and systems. Appliances such as LED lights and inverters among the highly performing electrical appliances perform better when wired with copper. Lower conductivity of aluminum may cause overheating and low efficiency of delicate electronics, which supports the superiority of copper once again.

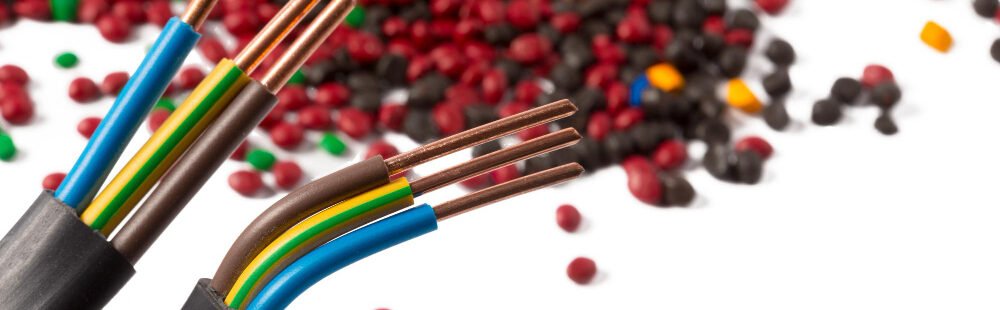

Cost vs. Value

Aluminum is cheaper in the short-term but copper is more economical in the long-run. Less power wastage, less maintenance and longevity imply that fewer replacements and repairs will be done and copper is therefore cheaper over the lifecycle of an electrical system of a building. This is the economic strength that has made the optimum cable manufacturing companies in India still focus on copper in their products.

Conclusion

Copper has the best conductivity, durability, corrosion resistance and compatibility with devices rendering it the preferred choice of wiring products. Although there are uses of aluminum, copper cannot be dispensed with in the modern electrical systems.

Empires Cables which is one of the major players in the market of copper building wire manufacture has always capitalized on the merits of copper to offer quality wiring solutions. They are committed to the use of premium copper which makes them reliable and efficient and they remain the best manufacturers of electrical wires in India.